Great prospects for digital development are underway for the NSE group. In fact, in order to authentically transcribe the production processes for its customers, the Group engages in a series of initiatives geared towards Factory 4.0.

The associated transformation aims to change the industrial dimension by adopting current and future technologies around the digital continuity of information, throughout the order process within the company.

The technological bricks initiated, or to come by NSE, include among others: time recording assisted by mobile terminal and QR code reader, digitization of quality control, monitoring and localization of tools, or digital continuity of the client's definition file. The latter subject is particularly concentrated from specification to manufacturing, with the aim of eliminating data repetitions during the design and industrialization phases.

The desired objectives are savings in results analysis time, simplification of data processing processes (through centralization) and reduction of external and / or internal non-quality.

A major asset for NSE since these solutions will also make it easier and faster to train employees in the various professions (wiring, integration, electrical and electronic processes, etc.)

A project supported by The Auvergne-Rhône-Alpes Region.

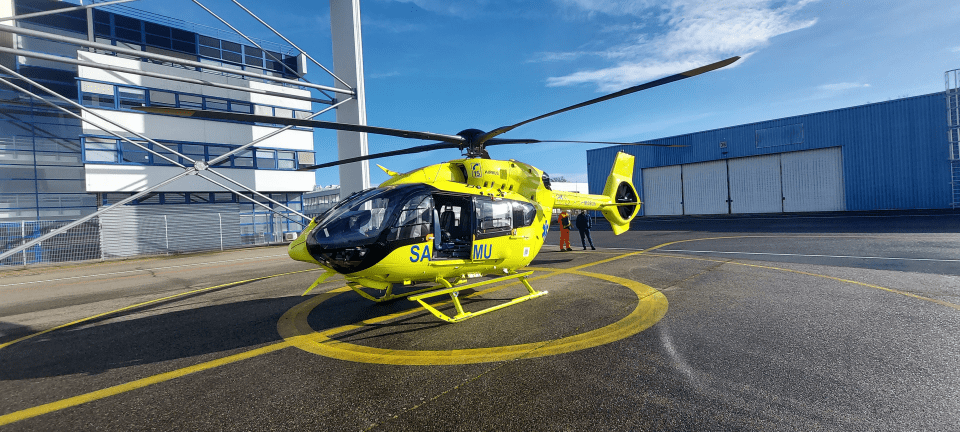

Since 1983, NSE has specialized in the development and implementation of complex on-board cabling systems, adapted to Defense, Aeronautics and of Industry.